In today’s manufacturing world, data is everywhere: on production lines, inside machines, and across connected devices. But the real breakthrough isn’t in collecting all that data; it’s in using it instantly to make smarter decisions.

That’s where Edge AI comes in.

Instead of sending everything to the cloud for processing, Edge AI brings intelligence closer to where data is created at the edge. This shift allows machines to see, hear, and understand their surroundings in real time, reacting within milliseconds. The result is a new era of manufacturing that’s faster, safer, and far more efficient.

Let’s explore 5 real-world ways Edge AI is transforming manufacturing operations today.

1. Flawless Visual Inspection

In a fast-moving production line, every second counts. Sending camera feeds to the cloud for defect detection is too slow to keep up.

With Edge AI, visual inspection happens directly on the device, analyzing each frame in real time. It spots microscopic defects, surface imperfections, or assembly errors as they occur ensuring consistent product quality without slowing production.

2. Predictive Maintenance That Prevents Downtime

Waiting for a machine to fail costs more than just repair time, it disrupts the entire workflow.

Edge AI enables predictive maintenance by locally analyzing vibration, temperature, and sound signals from equipment. It recognizes subtle anomalies that indicate wear or imbalance, allowing teams to intervene before breakdowns happen. The outcome: fewer surprises, less downtime, and greater reliability.

3. Enhanced Worker Safety

With Edge AI-powered vision systems, factories can detect and respond to hazards instantly. For example, if a worker steps into a restricted area or forgets protective gear, the system can trigger immediate, localized alerts to prevent accidents before they occur.

4. Smarter, Adaptive Robots

Conventional robots follow pre-programmed motions with little awareness of their environment.

Edge AI gives them the ability to see and adapt. Whether assembling parts that vary slightly in shape or handling irregular components, these robots can recognize patterns, adjust movements, and collaborate safely with humans all in real time.

5. A Self-Optimizing Supply Chain

Inventory errors and shipment delays can ripple through entire operations.

Edge AI integrates smart cameras and IoT sensors that monitor materials and inventory continuously. From barcode scanning to pallet tracking, the system maintains an accurate, real-time view of supply chain activity minimizing waste and ensuring smoother logistics.

The Perfect Partnership: Intelligence at Every Level

This evolution isn’t about replacing the cloud; it’s about balance.

- The Edge handles the immediate — the what and how — through instant data processing and localized decision-making.

- The Cloud delivers perspective — the why — aggregating data to train better models, improve processes, and drive long-term optimization.

Together, they create an intelligent feedback loop that allows enterprises to both react quickly and evolve strategically.

Sixfab: Powering Intelligence at the Edge

At Sixfab, we believe the future of manufacturing belongs to those who bring intelligence closer to the action.

Our industrial-grade Edge AI hardware and developer-ready tools give engineers, system integrators, and innovators everything they need to build the next generation of smart, autonomous factories where machines don’t just connect, they think.

If you’re ready to bring real-time intelligence to your operations whether on the production line, in the warehouse, or across your connected assets; now is the time to act.

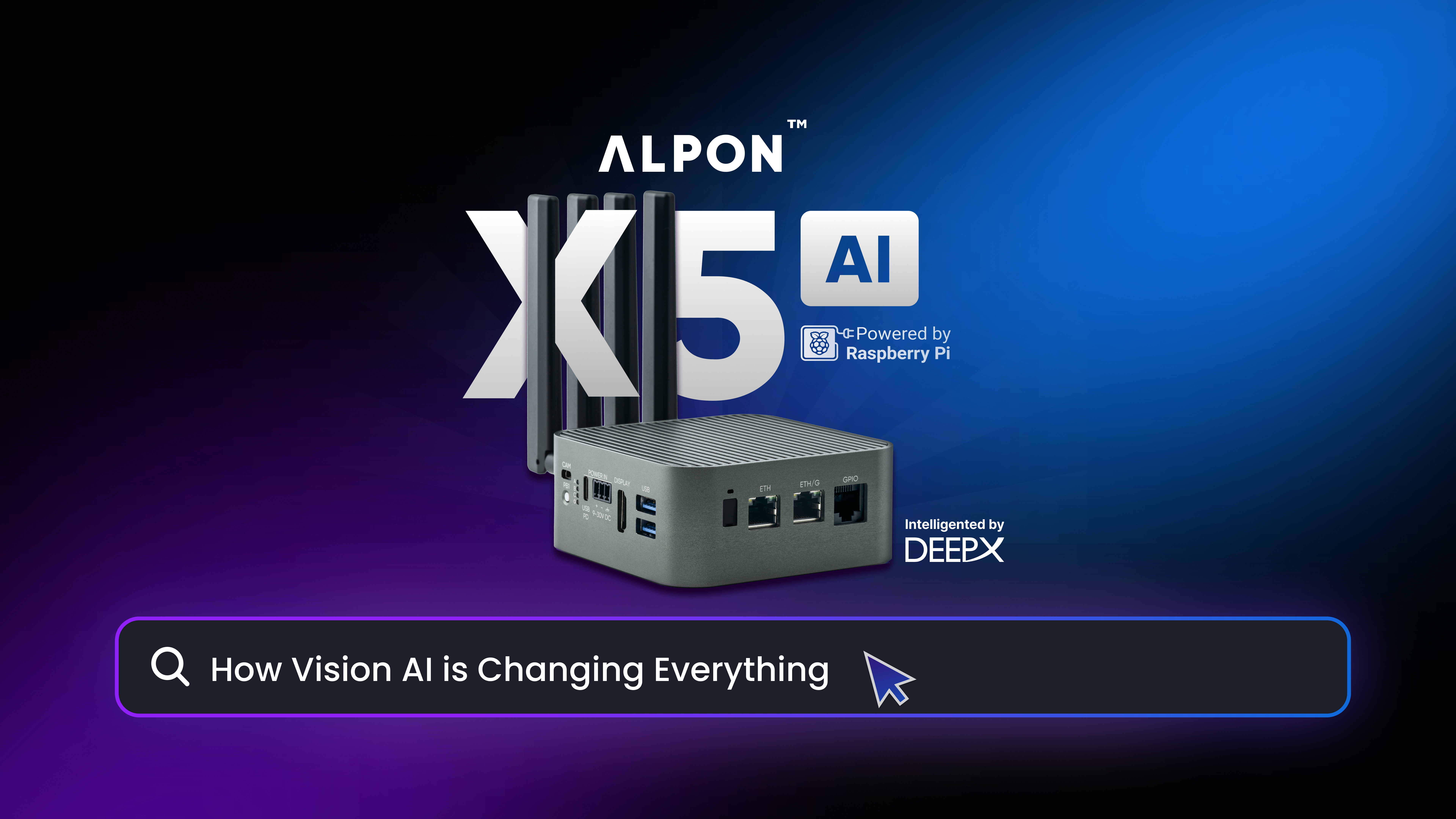

Explore how Sixfab’s ALPON can help you deploy Edge AI at scale.

Let’s build the future of manufacturing — right at the edge.