In the realm of industrial IoT (IIoT), uptime is critical to maintaining smooth operations. Unplanned downtime can lead to costly disruptions, lost productivity, and reputational damage. For industries relying on connected devices to monitor, manage, and automate systems, any network outage can halt operations and cause significant losses. A report by Siemens estimated that unplanned downtime now costs the world’s 500 biggest companies 11% of their revenues. That totals $1.4 trillion equivalent to the annual GDP of a major industrial nation like Spain.[1] The key to avoiding such pitfalls? A robust network redundancy strategy.

What is Network Redundancy?

Network redundancy refers to the inclusion of alternative communication pathways in a network, ensuring that data flow continues even if a primary route fails. For industrial IoT, where critical devices constantly communicate with central servers or cloud platforms, redundancy is essential. A single point of failure can render an entire system inoperative, affecting production lines, safety protocols, and supply chains.

Redundant systems provide backup connectivity using multiple networks (e.g., LTE, Wi-Fi, Ethernet) or devices, offering a safeguard against unexpected failures. Redundancy is not about avoiding issues entirely but about ensuring that even in the event of network problems, business continuity remains intact.

Types of Redundancy Solutions

To achieve network redundancy in IIoT systems, there are several effective strategies:

- Multi-Network Configurations

Combining different network types—such as cellular LTE, Wi-Fi, satellite, and Ethernet—can create a resilient communication system. If one network experiences issues, traffic can be redirected to the next available connection. For example, LTE networks provide wireless mobility, making them an excellent backup for fixed wired connections like Ethernet. - Automatic Failover Systems

Automatic failover mechanisms seamlessly switch the network to a backup system when the primary one fails. This ensures minimal downtime and prevents disruptions to critical IoT operations. Devices or gateways with built-in failover capabilities are particularly useful in harsh industrial environments where network conditions can be unpredictable.

According to the Uptime Institute’s 2023 survey, 31% of outages in mission-critical industries were caused by network and connectivity failure. Redundant setups can mitigate such risks [2]. - Geographically Diverse Redundancy

Having network servers or data centers located in different regions ensures that even if a physical location suffers from downtime (due to power loss, natural disaster, or network failure), IoT devices can still connect to the secondary site.

Implementing Redundancy in IoT Deployments

Setting up redundancy for industrial IoT environments requires careful planning. Here are steps to ensure effective redundancy:

- Identify Critical Systems: Not all IoT devices require redundancy. Focus on mission-critical systems whose downtime would lead to financial losses or safety issues.

- Leverage Redundant Hardware: Utilize redundant routers, switches, and gateways to prevent hardware-related outages. Many industrial IoT gateways come with dual SIM support, which helps in multi-network setups.

- Design for Scalability: Ensure that your redundancy architecture can scale with the growth of your IoT network. This includes adding new devices or incorporating new communication methods like 5G.

- Test and Monitor Failover Systems: Routine testing is crucial to ensure that failover mechanisms activate when required. Monitoring systems can alert you if a primary network is faltering, allowing for proactive responses before complete failure occurs.

Real-World Use Cases

In industries where operational continuity is critical, implementing network redundancy has proven to be a powerful safeguard against unexpected downtime. Whether in manufacturing, healthcare, logistics, or utilities, redundancy solutions ensure that business operations remain uninterrupted even when primary network connections fail. The following examples highlight how businesses have successfully implemented redundancy to maintain their operations and avoid costly interruptions:

Manufacturing: In manufacturing, network redundancy ensures that production lines remain operational even if there’s a primary network failure. For example, factories may use Ethernet as the primary network and LTE or 5G as a backup. If a wired connection fails due to hardware issues or environmental factors, the system seamlessly switches to wireless networks. Edge computing solutions designed for industrial applications ensures that IoT-connected devices, such as robotic arms or assembly line sensors, continue operating without interruption.

Oil, Gas, and Energy: Energy companies use IoT sensors to monitor pipelines, grid infrastructure, and other critical assets. Redundant network solutions, like LTE and satellite, ensure that these sensors stay online and can send real-time data about potential leaks, pressure changes, or equipment failures. This helps companies avoid downtime and ensures quick response times to critical situations. Redundant networks in remote locations, where wired networks are unavailable or unreliable, provide a backup solution to maintain operational continuity.

Healthcare: In healthcare, where real-time patient monitoring and telemedicine are critical, network redundancy ensures that life-saving devices and communication systems remain operational. Hospitals use redundant networks like LTE and satellite to back up primary wired connections for remote monitoring and cloud-based health applications. For example, in a situation where the hospital’s primary internet connection is disrupted, critical systems like remote ICU monitoring can fail over to a secondary network, ensuring continuous patient data flow and physician access.

Retail: Retailers use network redundancy to ensure that Point of Sale (POS) systems remain online, even during a primary network outage. Redundant connections allow for transactions, inventory tracking, and customer interactions to continue seamlessly, avoiding loss of sales and customer dissatisfaction. For instance, large global coffee chains utilize multi-network redundancy to ensure its POS systems are constantly connected, even in the event of a network outage, thus preventing disruptions in operations across its vast chain of stores.

Logistics: Logistics companies rely on network redundancy to track vehicles, shipments, and warehouse operations in real time. Major logistics companies use redundant cellular connections and GPS to ensure its fleet of vehicles can be monitored and managed even in remote areas or during network outages. By using multiple networks, including LTE and satellite, these companies can avoid costly delivery delays and ensure real-time communication with drivers and warehouses.

Explore Sixfab Industrial IoT solutions

In the highly connected world of industrial IoT (IIoT), uptime is critical to success. Network redundancy plays a vital role in ensuring that business operations can withstand unexpected network failures. By implementing multi-network configurations, automatic failover systems, and routine monitoring, industrial businesses can safeguard their systems from costly downtime. Planning for redundancy is essential in the design phase of any IoT project, as it not only protects operations but also increases resilience in an increasingly interconnected world.

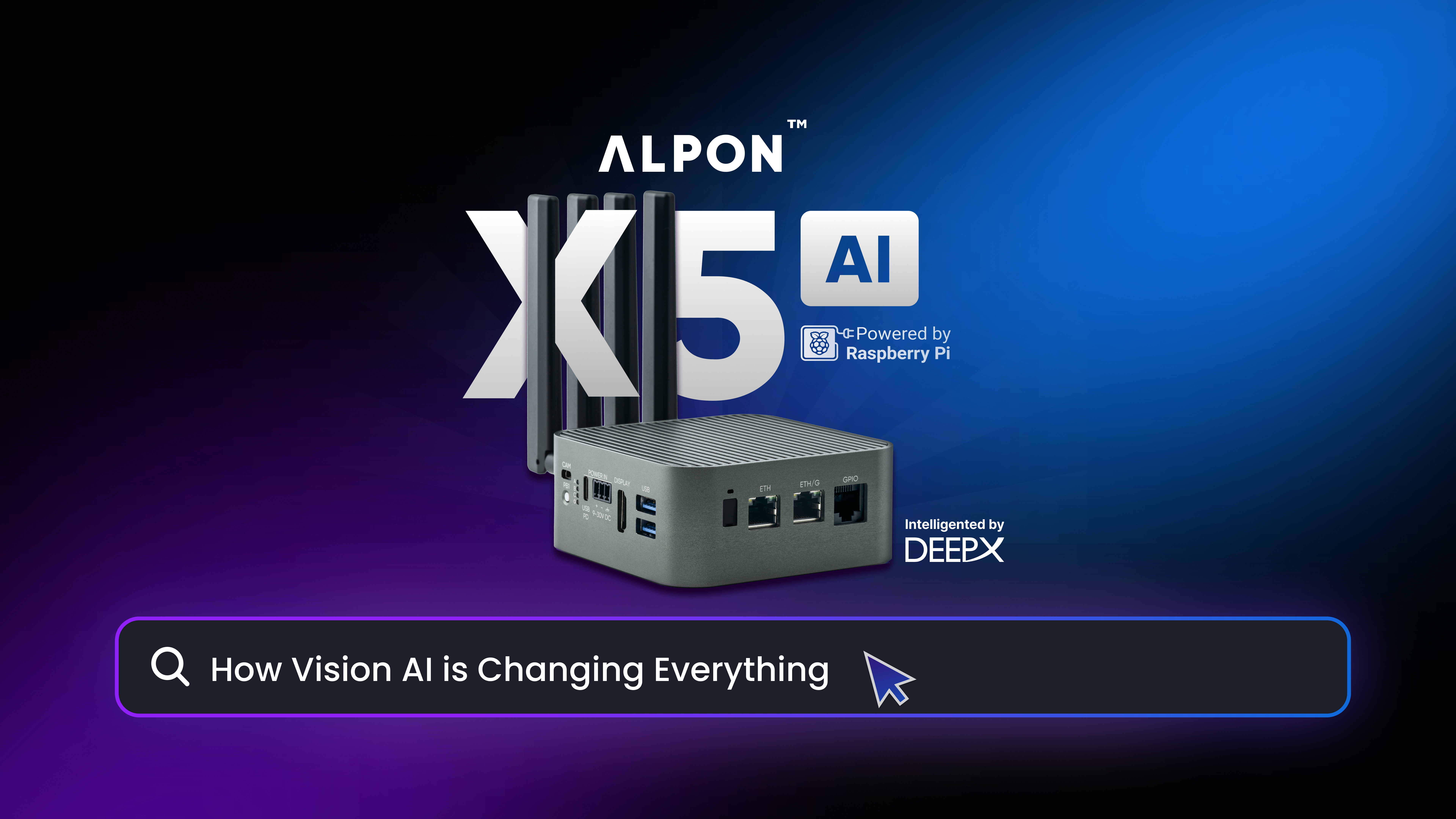

To explore how Sixfab Industrial IoT solutions—including our latest innovation, Alpon X4— can help you implement robust network redundancy and maximize your system’s uptime, connect with our experts.

Bibliography

[1] The True Cost of Downtime 2024, by Siemens source

[2] Annual outage analysis 2023: The causes and impacts of IT and data center outages, by Andy Lawrence and Lenny Simon, March 2023. source