Managing large fleets of IoT devices can be a logistical nightmare for companies across industries. Traditional methods of maintaining these devices often require significant time and resources. Field technicians must physically visit each device to perform diagnostics, updates, or repairs, which can be inefficient and costly. Moreover, with devices scattered across vast geographic locations, troubleshooting and addressing problems promptly can be a complex, resource-intensive task. These traditional maintenance strategies often result in downtime, increased operational costs, and slower issue resolution, making it clear that more efficient solutions are necessary.

What is Remote Monitoring?

Remote monitoring refers to the use of technology to continuously monitor the health, performance, and status of IoT devices from a central location without the need for on-site visits. It typically involves the deployment of sensors and software that can transmit real-time data back to a monitoring center. For IoT devices, this means operators can track metrics such as device uptime, battery life, connectivity, temperature, and other operational parameters. Remote monitoring plays a critical role in enabling proactive maintenance, as it allows teams to identify and address issues before they escalate into major problems.

Benefits of Remote Monitoring

IoT remote monitoring solutions address the pain points effectively by providing real-time data and instant alerts. With the capability to access crucial data instantly, companies can verify compliance requirements without delays, keeping production running smoothly.

Furthermore, by harnessing real-time insights, manufacturers can optimize their processes and make informed decisions to enhance efficiency. In essence, IoT remote monitoring serves as a critical tool for businesses seeking to boost productivity, reduce costs, and achieve operational excellence.

Lower Operational Cost: With fewer field visits, companies can significantly reduce their operational costs. Technicians no longer need to travel to remote locations or spend time on-site performing routine tasks. This leads to savings on travel expenses, labor costs, and overall downtime. Remote monitoring also optimizes the scheduling of maintenance tasks by providing data-driven insights, helping teams to plan better and avoid unnecessary expenses.

Quicker Problem Resolution: Issues can often be detected and diagnosed remotely, allowing teams to respond much more quickly than if they had to wait for a technician to arrive. If a problem is identified, remote fixes such as software updates or configuration changes can be implemented instantly. In many cases, if a device is malfunctioning, it can be remotely rebooted, or its settings adjusted to restore functionality immediately, minimizing downtime.

Sustainability: Remote monitoring also plays a significant role in promoting sustainability. By reducing the need for physical visits to IoT devices, companies can lower their carbon footprint, as fewer travel-related emissions are generated. Additionally, with real-time performance tracking, businesses can optimize device usage and maintenance schedules, extending the lifespan of their equipment and reducing the need for replacements. This leads to less electronic waste and a more efficient use of resources, contributing to overall environmental sustainability goals. Remote monitoring, therefore, not only enhances operational efficiency but also supports a greener, more sustainable future for industries that rely on IoT technology.

Key Features to Look for in a Remote Monitoring Solution

Real-Time Monitoring

A robust remote monitoring solution should offer real-time tracking of devices, including metrics such as battery levels, signal strength, connectivity status, and overall device performance. This ensures that any potential issue is detected early, reducing the chances of unexpected failures.

Remote Diagnostics

With remote diagnostics, teams can assess the health of IoT devices without needing to be physically present. This feature allows operators to view error codes, troubleshoot issues, and determine whether a device requires immediate attention or if the problem can be resolved remotely.

Automated Alerts and Notifications

Automated alerts are an essential feature of any remote monitoring solution. These notifications can be configured to alert technicians when specific thresholds are met or when abnormalities are detected, such as a drop in connectivity or an impending failure. This feature ensures that maintenance teams are always aware of device statuses and can act quickly to resolve problems.

Data Analytics and Reporting

Advanced remote monitoring solutions often come with built-in data analytics tools. These tools analyze the data collected from devices over time, providing insights into performance trends, potential weaknesses, and areas for improvement. This helps companies to optimize their IoT infrastructure and make informed decisions about maintenance schedules and device replacements.

Improved Security and Safety

Enhanced workplace safety is another significant advantage of a comprehensive IoT remote monitoring solution. By continuously tracking operational processes and environmental conditions, these systems can detect potential hazards in real time, such as overheating machinery or unsafe levels of harmful gases. This early detection allows businesses to implement preventive actions swiftly, reducing the risk of accidents and ensuring a safer environment for employees. By integrating safety alerts into the monitoring system, companies can proactively address issues before they escalate, promoting a culture of safety and compliance across the organization.

Industries Benefiting from Remote Monitoring

Industrial Sector

In industries like manufacturing and logistics, remote monitoring plays a crucial role in maintaining machinery and equipment. By monitoring the health of industrial IoT devices remotely, companies can detect potential issues before they cause downtime, reducing maintenance costs and enhancing operational efficiency.

Energy Sector

Remote monitoring is particularly beneficial in the energy sector, where industrial IoT devices are often deployed in remote and hard-to-reach locations, such as wind turbines, solar panels, or oil rigs. Real-time monitoring allows companies to track the performance of energy assets and quickly address any issues that may arise, reducing the risk of costly outages.

Transportation Sector

The transportation industry relies heavily on IoT devices to monitor vehicles, fleets, and infrastructure. Remote monitoring enables companies to keep track of vehicle health, fuel efficiency, and location in real time. This leads to improved fleet management, better route planning, and increased safety on the roads.

The Shift Toward Remote Monitoring in IoT Management

As IIoT ecosystems continue to expand, the need for efficient and cost-effective maintenance strategies has never been greater. Remote monitoring provides a solution that not only reduces operational costs and minimizes downtime but also improves the speed and effectiveness of troubleshooting. The transition to remote monitoring is not just a trend but a fundamental shift in how IoT devices are managed, and it is quickly becoming a best practice in the industry. As more companies recognize the value of remote monitoring, it is clear that this technology will continue to play a central role in the evolution of IIoT device maintenance.

Ready to Transform IIoT Management with Sixfab?

If you’re ready to take your IIoT device management to the next level, Sixfab offers cutting-edge remote monitoring solutions designed to improve efficiency, reduce costs, and enhance sustainability. Whether you’re in industrial, energy, or transportation sectors, our advanced industrial IoT connectivity solutions provide the tools you need for seamless device management and real-time diagnostics.

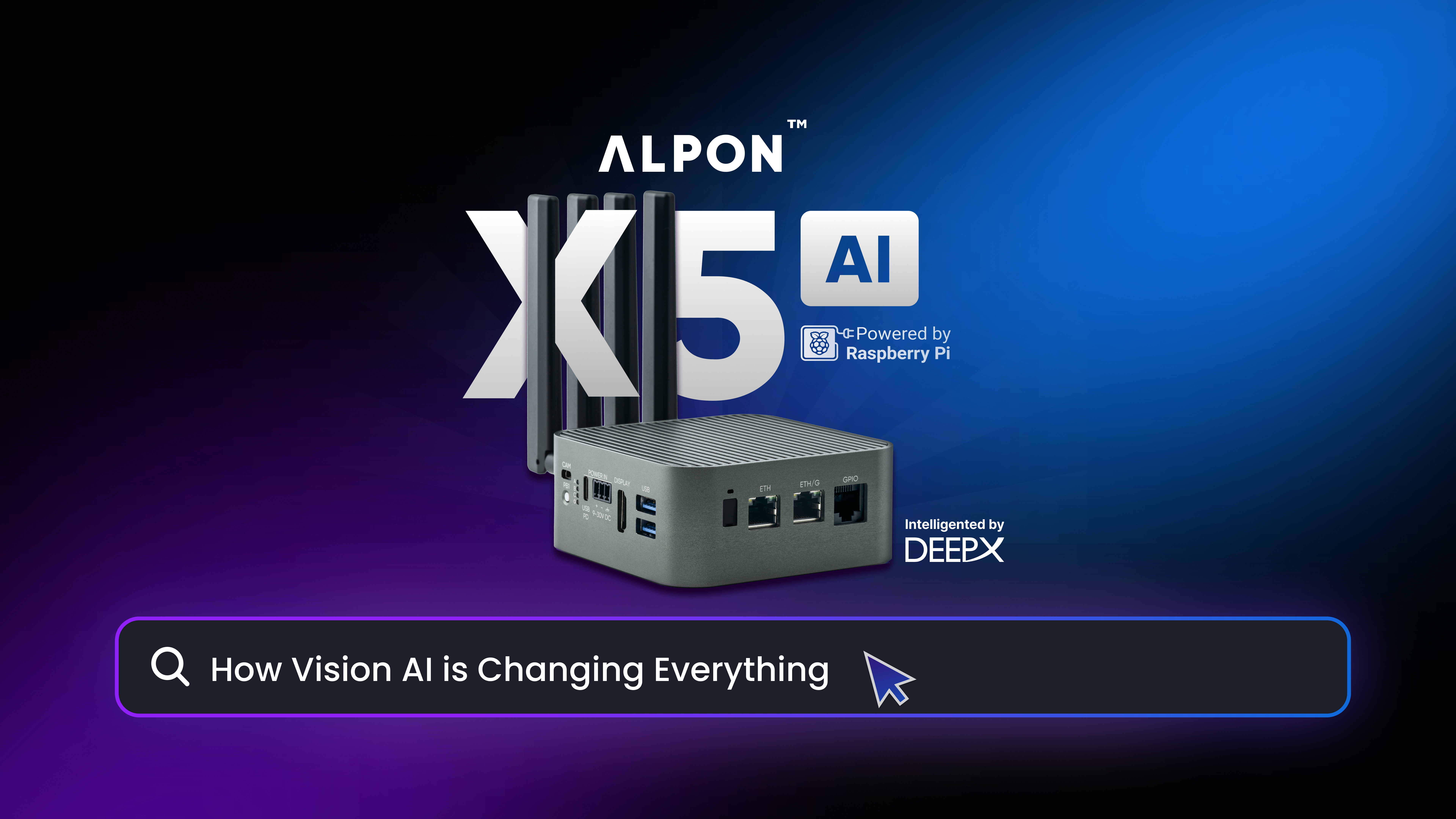

Experience the future of IIoT with Alpon X4, Sixfab’s latest innovation in edge computing. With Alpon X4, you can reimagine the possibilities of edge device management and unlock unparalleled value.

Contact us today to learn how Sixfab and Alpon X4 can help you optimize your IoT fleet and stay ahead of the curve in the rapidly evolving world of connected devices.