Raspberry Pi is in use by many businesses to help in the design process of their products. This not only saves time but reduces risks and provides a higher-quality end product. If you have an idea or product and need help with integrating Raspberry Pi together with it, contact us for help.

Every Design Partner is reviewed and approved by Raspberry Pi to ensure we have technical and commercial abilities to design your product to your requirements.

The next step of your idea in the journey of edge computing.

Turn your concept with Raspberry Pi into a product with Sixfab’s experience in IoT.

- Realize your idea with better electronics

- Have an engineering sample in weeks

- Get production at any quantity

Bring your concept to Life.

If your idea is …

- Based on any version of Raspberry Pi

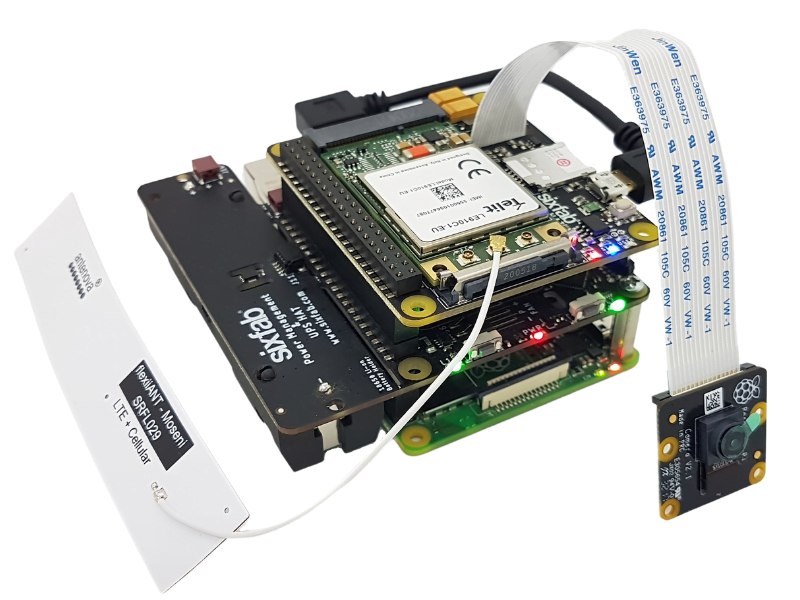

- Validated by a proof of concept (PoC) with multiple HATs or breakout boards

- Connected via cellular

We can design the hardware that will help you skip months of trial and error.

Our expert team designs a tailor-made Raspberry Pi HAT with features from your multiple HAT stacked PoC and more.

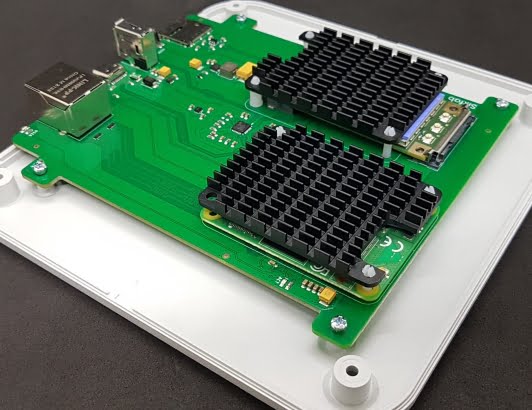

We provide Raspberry Pi Compute Module based custom-designed product for increased reliability.

All you need is Sixfab’s global SIM Connectivity and CORE Software to use edge devices cellular reliably.

What is included in this service?

- Fully assembled DFM prototypes

- Production at any quantities

- Design files and hardware instructions

- Branded enclosure solutions

- Regulatory consultation and radio pre-tests

Our team, as your team,

R&D with transparency

| 2w | 4w | 6w | 8w | 10w | 12w | 14w | 16w | 18w | 20w | 22w | 24w | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Onboarding | ||||||||||||

| Budgeting | ||||||||||||

| Development | ||||||||||||

| Prototyping | ||||||||||||

| Hello World | ||||||||||||

| Validation | ||||||||||||

| Pre-production | ||||||||||||

| Production |

1- Onboarding

Bringing the idea to the workbench with mutually agreed technical specification and product requirements. 1 Week

2- Budgeting

Planning project budget and accurate time frame quote followed by the agreement. 1 week

3- Development

The team exercises research and finalizes hardware design in 6-12 weeks.

Milestone: Customer can review design images in 2D/3D.

4- Prototyping

Prototype manufacturing at fastest and high-quality facilities. 2 weeks

5- Hello World

First prototype evaluation. Sixfab tests the functionality of the product. The team fixes the design if necessary, completes esthetic touches and ensures connector mating and takes another prototype. 2-3 weeks

Milestone: Customer receives DFM prototypes.

6- Validation

Customer runs real application and field tests, validates prototypes, approves functionality, leaves feedback. 1-3 weeks

7- Pre-production

Final prototype designed and manufactured if needed updates. 2-3 weeks

8- Production

Manufacturing at any quantity. 8 Weeks

Quality as a Standard

Certificates of manufacturing facilities we partner

Proven industry-grade sub-components we use