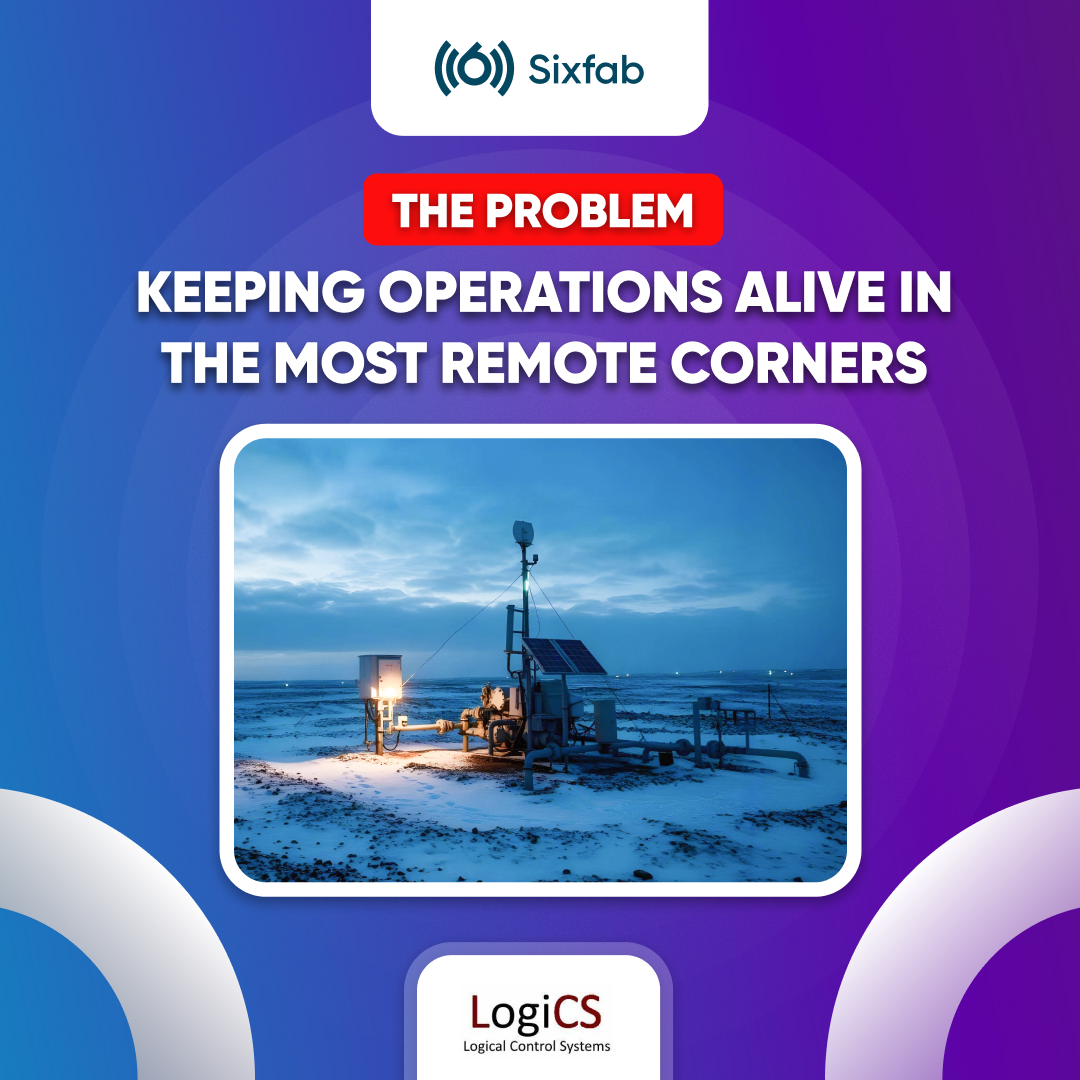

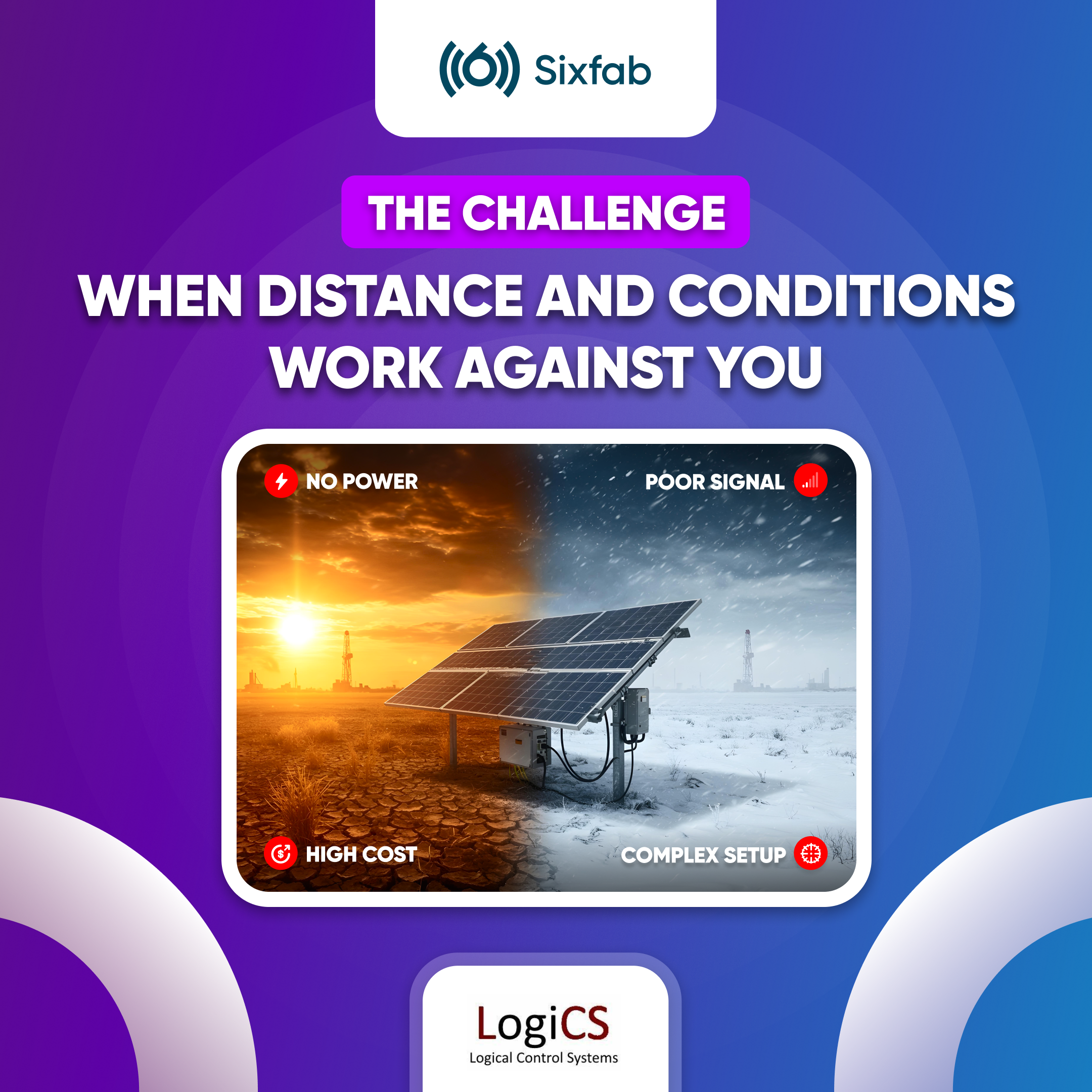

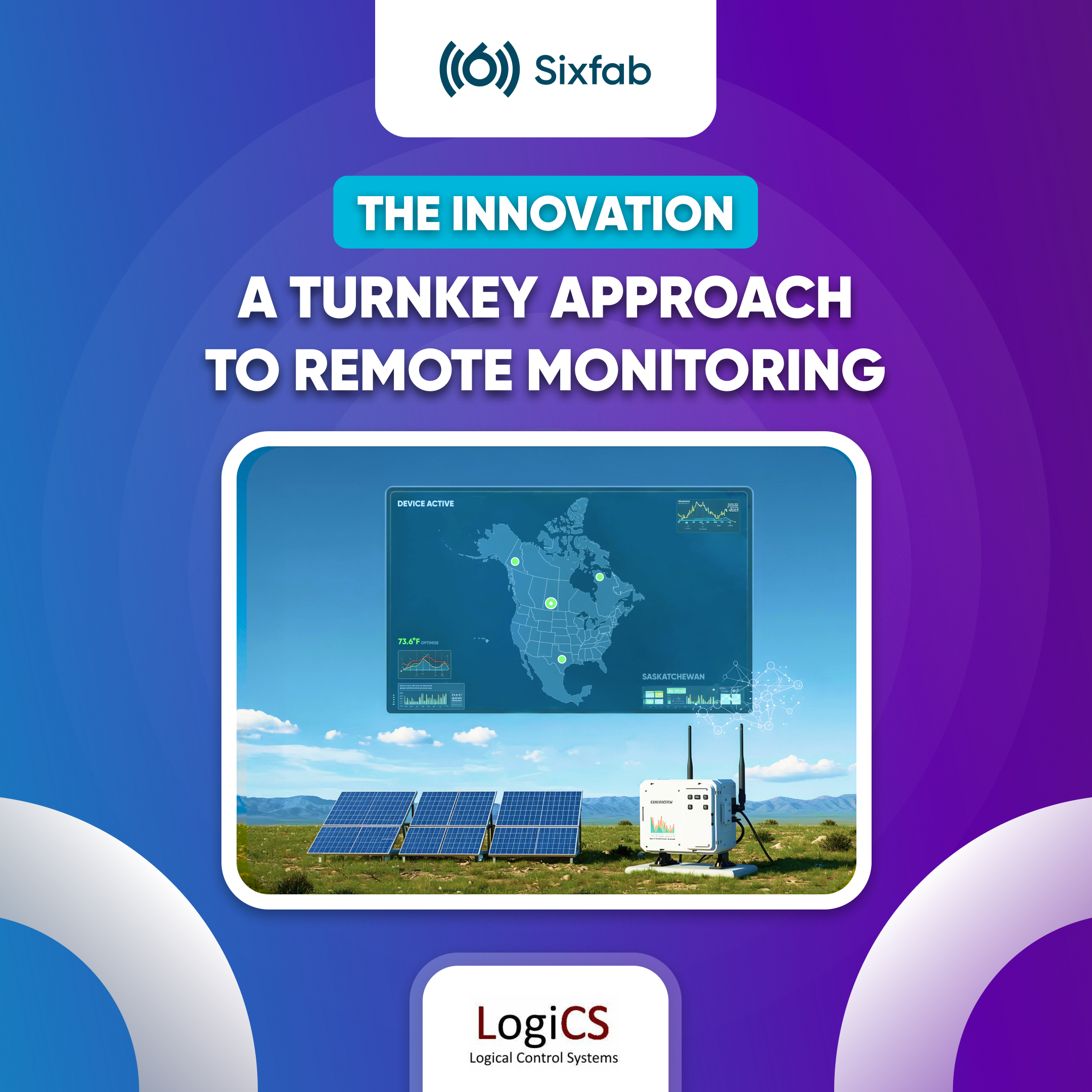

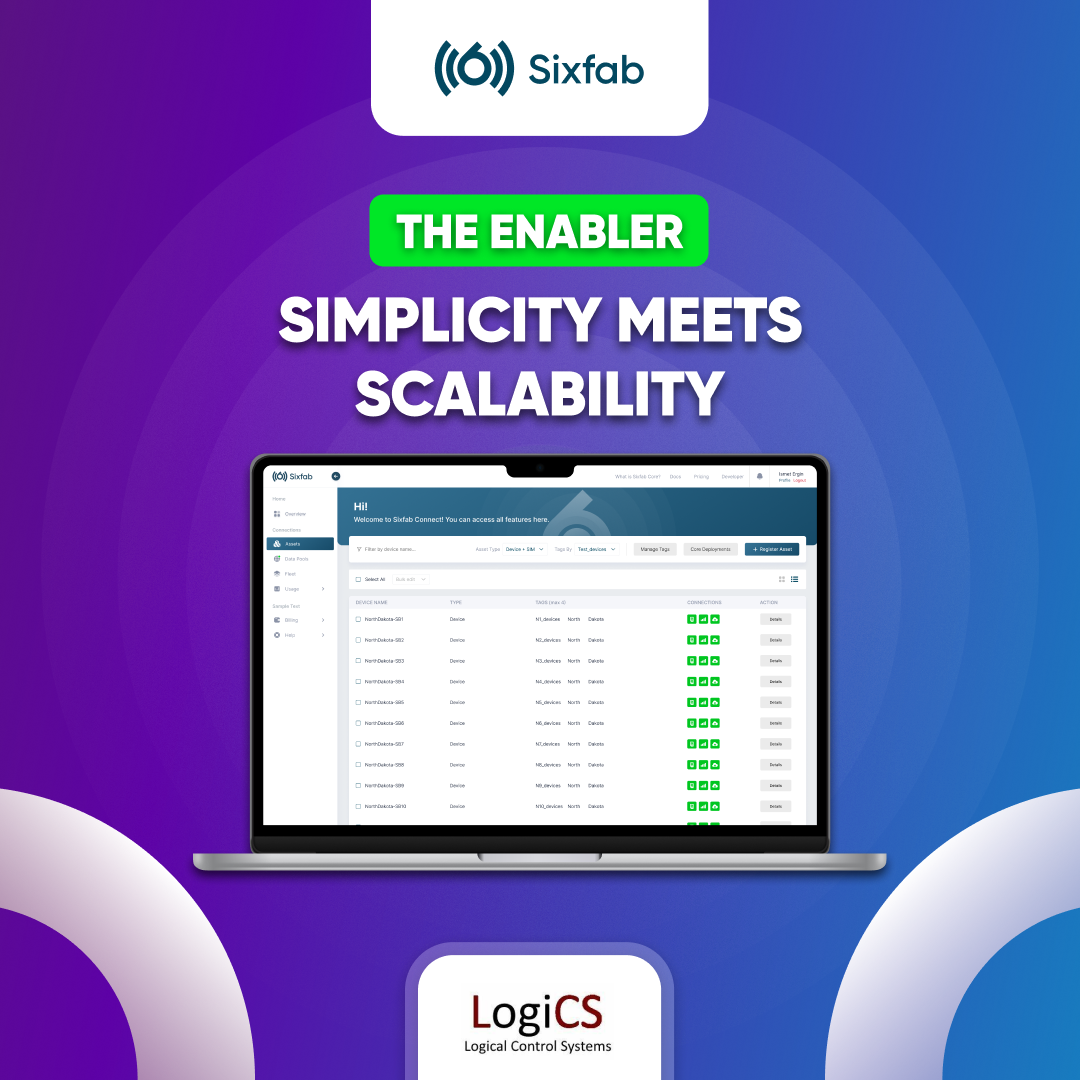

In industries like oilfield and agriculture, critical assets often sit in isolated locations far from power grids and reliable connectivity. Extreme weather, from scorching summers to freezing winters, adds another layer of complexity. For Logical Control Systems, the challenge was clear: How do you monitor and control remote equipment when traditional infrastructure fails? Their customers needed real-time data, alerts, and control without exorbitant costs or unreliable patchwork solutions.